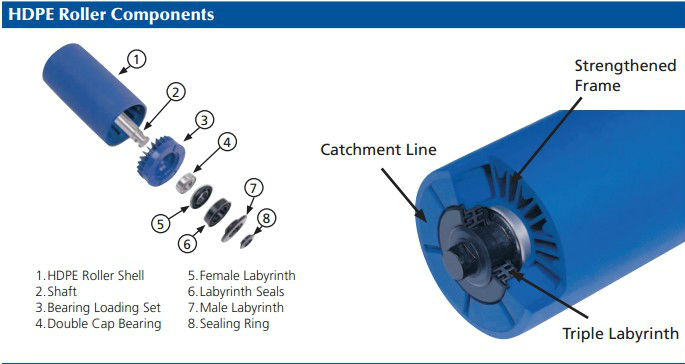

HDPE ROLLERS

HDPE Conveyor Rollers are designed to provide a longer operating life than steel rollers, especially in dirty and wet conditions.

Designed to handle the same capacity as an equivalent steel roller, the provides a non-corrosive shell and additional static face sealing system to further limit the ingress of dirt.

HDPE rollers have been used extensively on conveyors transporting abrasive sand, iron ore, gold and platinum ore and coal.

The HDPE can be supplied in many lengths and in a range of diameter and shaft combinations.

| Diameter (mm) | Shaft series (mm) |

|---|---|

| 102 | 25 |

| 114 | 25 |

| 127 | 25 |

| 133 | 25 |

| 152 | 25, 30, 40 |

| 159 | 25, 30, 40 |

| 178 | 40 |

LOWER MASS

The SUPREME roller is lighter than an equivalent steel roller making for safer handling especially on larger rollers. The lower rotating mass reduces the start-up torque required for the conveyor.

| Steel | HDPE | % Change | % Change | |||

|---|---|---|---|---|---|---|

| Roller Size | Total Mass | Rotating Mass | Total Mass | Rotating Mass | Mass | Rotating Mass |

| 127/340/25 | 6.8 | 5.5 | 5.3 | 4.0 | -22% | -37% |

| 127/390/25 | 7.5 | 6.0 | 5.9 | 4.4 | -21% | -36% |

| 152/450/30 | 12.2 | 9.7 | 10.6 | 8.1 | -13% | -19% |

| 152/560/30 | 14.4 | 11.3 | 12.5 | 9.4 | -13% | -20% |

| 152 | 127 diam | |||||

|---|---|---|---|---|---|---|

| Belt speed | St | HDPE | Diff | Steel | HDPE | Diff |

| 4,2 m/sec | 78 | 65.5 | 12.5 | 74.6 | 65.5 | 9.1 |

| 3,2 m/sec | 73 | 62.5 | 11 | 67.3 | 62.5 | 4.8 |

| 1,2 m/sec | 54 | 52.8 | 1.7 | 53.6 | 51.5 | 2.1 |

QUIETER ROLLER

Conveyor noise is an environmentally sensitive issue. The HDPE rollers have a significantly lower noise emission than steel rollers.